Page 1 of 1

Total rudder rebuild: hull #18 Fionn

Posted: Wed Nov 20, 2024 8:00 pm

by Bob McGovern

Our Ballad's rudder was damaged, and water intrusion led to blistering.

- GEDC0910.JPG (124.44 KiB) Viewed 45787 times

I split it like an oyster and found the stock was okay, but the interior was delaminated and the foam was rotten.

- clam.JPG (152.06 KiB) Viewed 45787 times

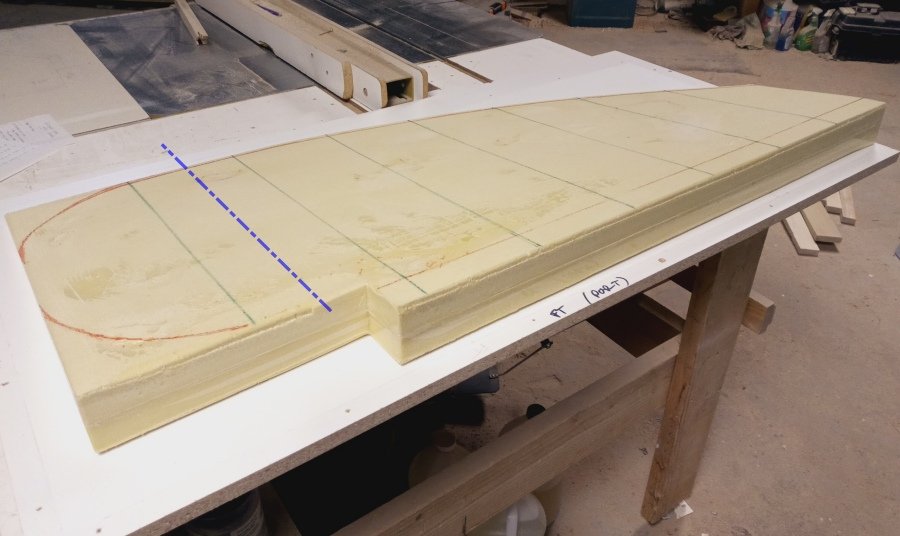

So we re-used the stock and made a new, better-shaped blade from scratch. First step was pouring two mirrored blanks from 16lb/cuft (256kg/m^3) urethane foam. Total foam use was 1 cuft kit (0.03 m^3).

- blank.jpg (57.14 KiB) Viewed 45787 times

Molds were waxed melamine with wooden perimeter rails, poured interior faces against the melamine. Two blanks stacked and ready to shape:

- IMG_20230402_195356_580.jpg (69.18 KiB) Viewed 45787 times

Re: Total rudder rebuild: hull #18 Fionn

Posted: Wed Nov 20, 2024 8:09 pm

by Bob McGovern

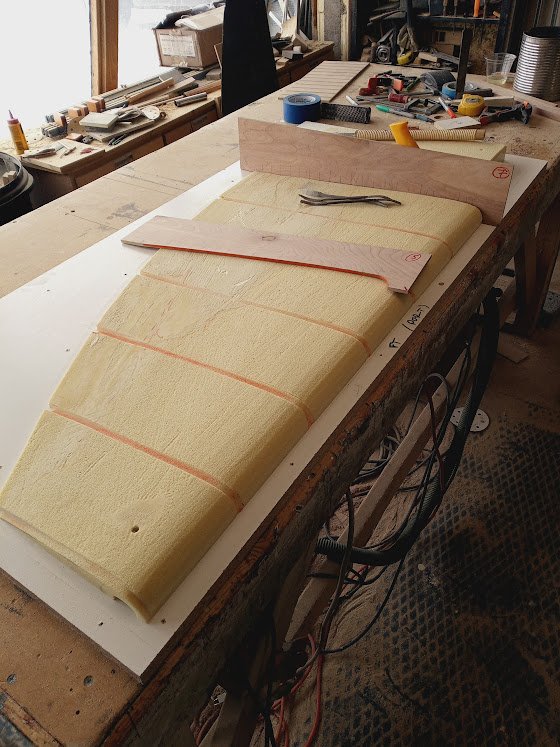

Next the halves were rough-shaped to templates.

- IMG_20230404_171015_865.jpg (104.01 KiB) Viewed 45786 times

The bottom extension, which is semi-sacrificial, was sawn off square to the leading edge, to be reattached later. Top and bottom plates were sawn and shaped from a 6mm slab laid up on melamine.

- top bott caps.jpg (120.29 KiB) Viewed 45786 times

The foam blanks were roughed up and relieved to accept the stock, with thickened epoxy bedding:

- IMG_20230407_154332_687.jpg (87.01 KiB) Viewed 45786 times

Finally the halves were epoxied together (stock embedded in G*Flex to squeezeout), and the bottom section was attached using 3/8" (10mm) GRP battens (shop made).

- IMG_20230408_122251_163.jpg (62.89 KiB) Viewed 45786 times

- IMG_20230408_122303_963.jpg (66.32 KiB) Viewed 45786 times

Re: Total rudder rebuild: hull #18 Fionn

Posted: Wed Nov 20, 2024 8:19 pm

by Bob McGovern

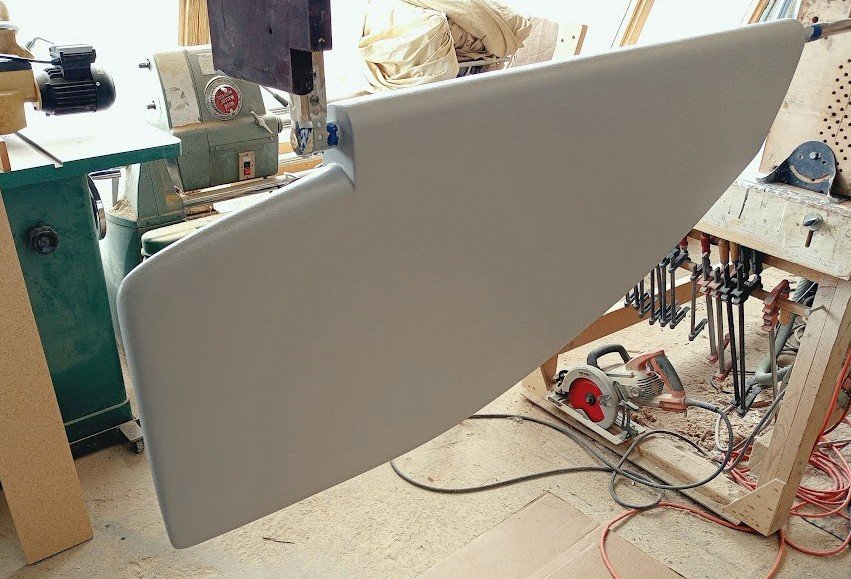

Final shaping of the rudder to templates, followed by hand-layup of epoxy GRP:

- IMG_20230411_115049_159.jpg (95.19 KiB) Viewed 45785 times

- drape.jpg (139.71 KiB) Viewed 45785 times

Schedule was 5 layers of 1805 biax with sewn mat backing, done in two sessions. Then two layers of medium woven fabric and one of veil for waterproofing. Some sanding and fairing between each session.

- battens.jpg (190.23 KiB) Viewed 45785 times

- trailing2.jpg (83.55 KiB) Viewed 45785 times

Trailing edge is created by clamping together laminations with curved battens. Final laminate thickness is 1/4" (7mm), a bit more on the rudder bottom.

Re: Total rudder rebuild: hull #18 Fionn

Posted: Wed Nov 20, 2024 8:26 pm

by Bob McGovern

Finally, a bit of sanding and fairing, followed by two coats of hi-build epoxy barrier coat and three coats of a waterbased antifouling copolymer.

- epoxy primed.jpg (130.22 KiB) Viewed 45783 times

- bottom painted.jpg (74.51 KiB) Viewed 45783 times

A bit dusty from sitting in the shop for eight months, but finally got it mounted:

- IMG_20241028_152105_892.jpg (103.57 KiB) Viewed 45783 times

New Delrin bearings throughout, custom made by a person on eBay. This shape should be more slippery, with better bite down low and less induced drag around the bottom. Total cost was around $350 USD. Probably 100 hours of labor; someone better at composites could do it faster.